Masana'antar Baturi Da Sauran Abubuwan Sinadarai Amfani da Jikin Jet Mai Ruwa Mai Ruwa

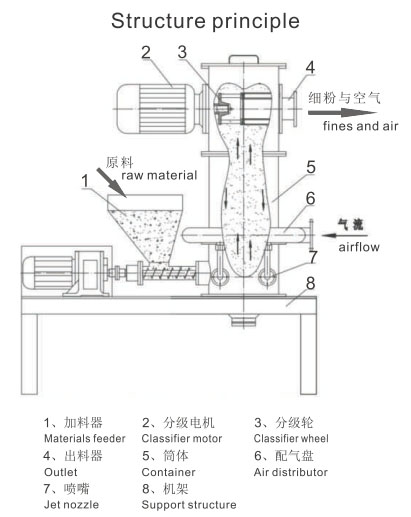

Fluidized bed pneumatic niƙa shine kayan aikin da ake amfani da su don murƙushe busassun kayan zuwa foda mai kyau, tare da tsarin asali kamar haka:

Samfurin shine mai juzu'in gado mai ruwa tare da matsewar iska azaman matsakaicin murkushewa. Jikin niƙa ya kasu kashi 3, wato wurin murƙushewa, wurin watsawa da wurin grading. An samar da Wurin Grading tare da dabaran tantancewa, kuma ana iya daidaita saurin ta mai canzawa. Dakin murƙushewa ya ƙunshi bututun murƙushewa, mai ciyar da abinci, da dai sauransu. Ana haɗa diskin zoben sir wadata a waje da gwangwanin murƙushewa tare da bututun murƙushewa.

Kayan yana shiga ɗakin murƙushewa ta hanyar ciyar da kayan. Iskar da ke matsawa ta shiga cikin dakin da take murkushewa cikin sauri ta cikin na'urorin murkushe nozzles guda hudu na musamman. Kayan yana samun haɓakawa a cikin jigilar jetting na ultrasonic da kuma tasiri akai-akai da yin karo a tsakiyar haɗuwa na ɗakin murƙushewa har sai an murkushe shi. Kayan da aka murkushe yana shiga dakin grading tare da haɓakawa. Saboda ƙafafun grading suna jujjuya cikin babban gudu, lokacin da kayan ya hau, ɓangarorin suna ƙarƙashin ƙarfin centrifugal da aka ƙirƙira daga rotors grading da kuma centripetal ƙarfin da aka kirkira daga danko na iska. Lokacin da barbashi ke ƙarƙashin ƙarfin centrifugal wanda ya fi ƙarfin centripetal, ƙananan barbashi masu girman diamita fiye da abubuwan da ake buƙata ba za su shiga ɗakin ciki na dabaran grading ba kuma za su koma ɗakin murƙushewa don murkushe su. Kyawawan ɓangarorin da suka dace da diamita na abubuwan da ake buƙata za su shiga cikin dabaran ƙira kuma su gudana cikin mai raba guguwa na ɗakin ciki na dabaran grading tare da kwararar iska kuma mai tarawa ya tattara shi. Ana fitar da iskar da aka tace daga mai shan iska bayan maganin jakar tacewa.

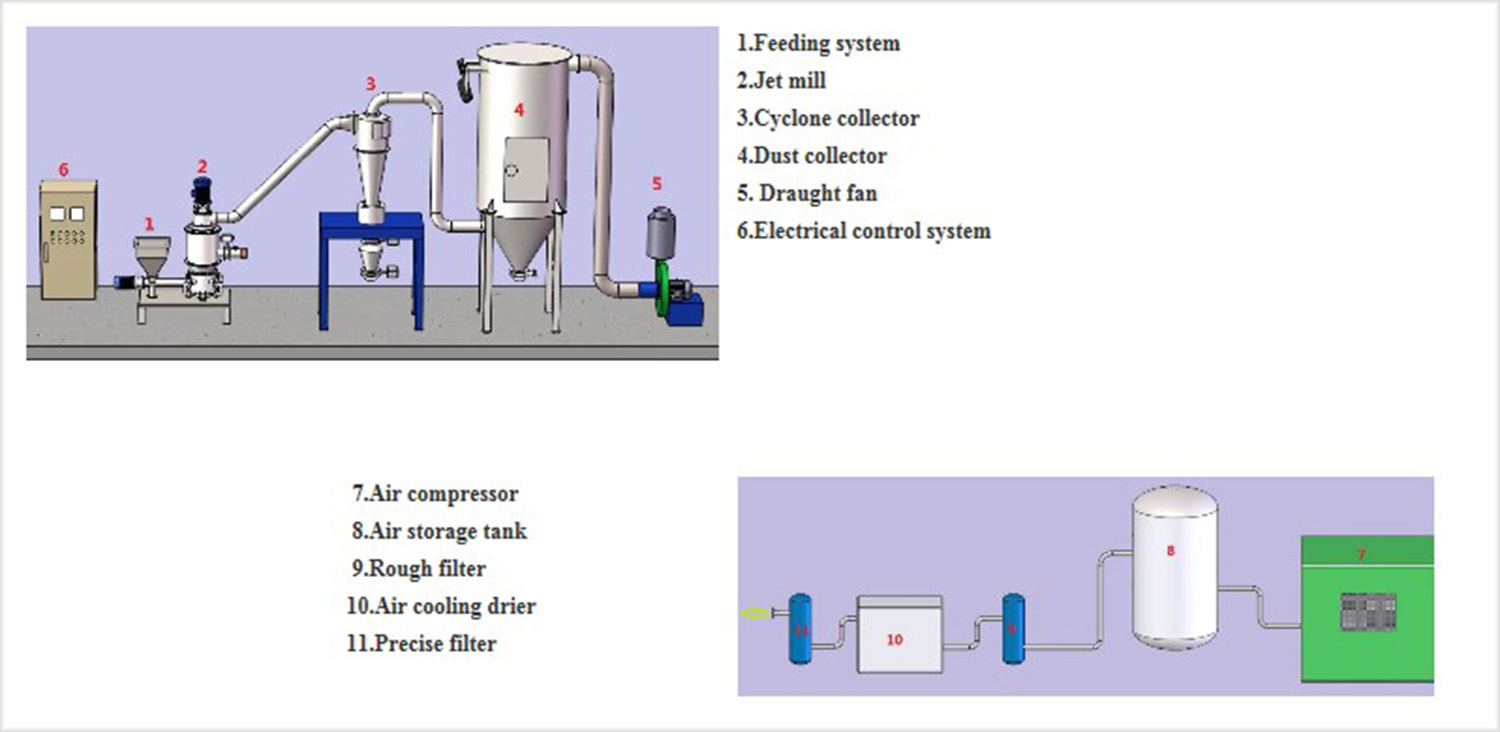

A pneumatic pulverizer an hada da iska kwampreso, mai remorer , gas tanki, daskare bushewa, iska tace, fluidized gado pneumatic pulverizer, cyclone SEPARATOR, tara, iska ci da sauransu.

Nunin dalla-dalla

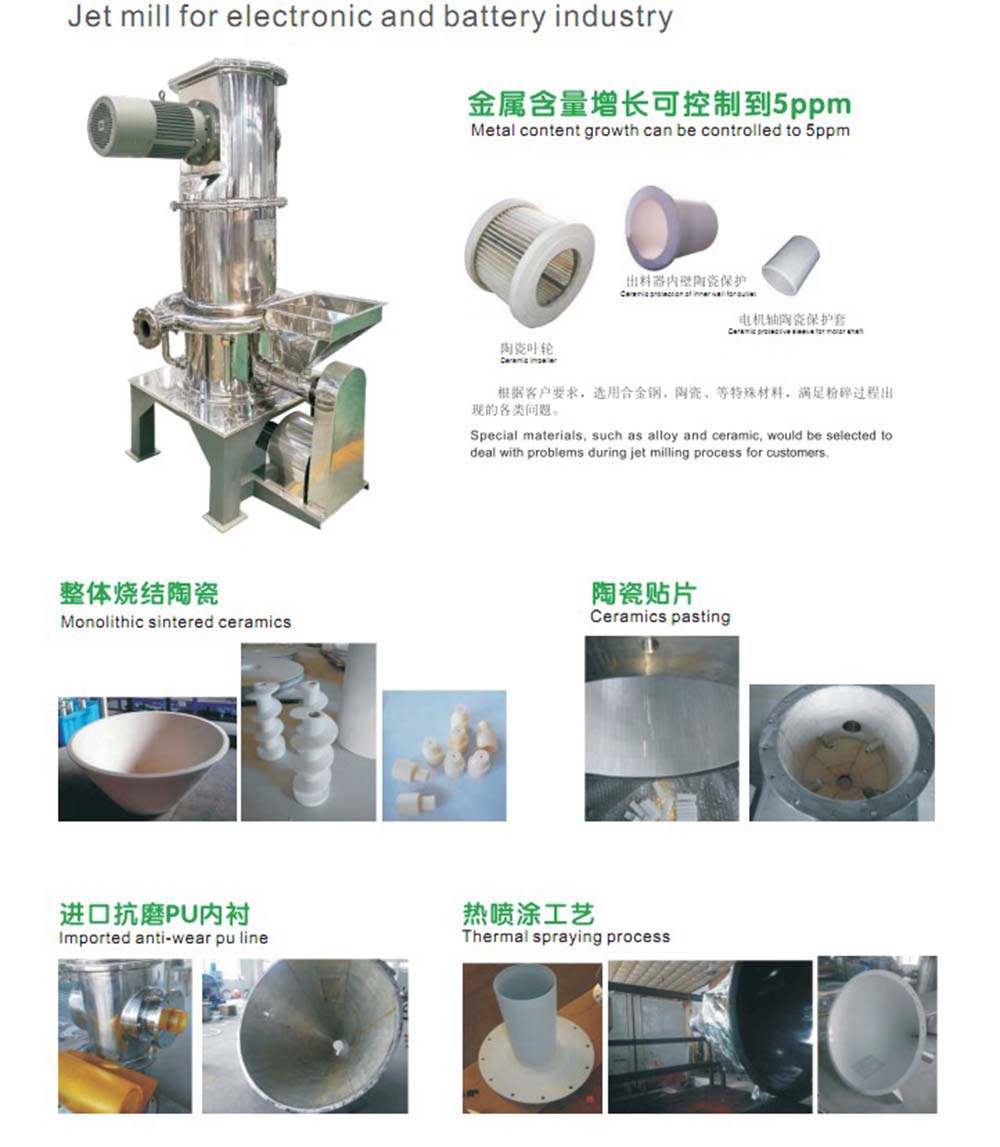

Lin ɗin yumbura da rufin PU a cikin sassan niƙa gabaɗayan tuntuɓar samfura don guje wa ƙera baƙin ƙarfe shan gubar zuwa mummunan tasirin samfuran ƙarshen.

1.Precision yumbu mai rufi, 100% kawar da gurɓataccen ƙarfe daga tsarin rarraba kayan aiki don tabbatar da tsabtar samfurori. Musamman dacewa da buƙatun abun ciki na ƙarfe na kayan lantarki, irin su cobalt high acid, lithium manganese acid, lithium iron phosphate, Ternary Material, lithium carbonate da Acid lithium nickel da cobalt da dai sauransu baturi cathode abu.

2. Babu hawan zafin jiki: Yanayin zafin jiki ba zai karu ba yayin da kayan da aka tarwatsa su a ƙarƙashin yanayin aiki na fadada pneumatic kuma ana kiyaye yawan zafin jiki a cikin rami mai niƙa.

3.Endurance: Aiwatar da kayan da Mohs Hardness da ke ƙasa da Grade 9. tun da tasirin milling kawai ya ƙunshi tasiri da karo tsakanin hatsi maimakon karo da bango.

4.Energy-tasiri: Ajiye 30% -40% idan aka kwatanta da sauran iska pneumatic pulverizers.

5.Inert gas za a iya amfani da shi azaman kafofin watsa labarai don milling flammable da abubuwa masu fashewa.

6. Dukkan tsarin yana rushewa, ƙura yana da ƙasa, ƙarar ƙararrawa, tsarin samarwa yana da tsabta da kare muhalli.

7. Tsarin yana ɗaukar kulawar allon taɓawa ta hankali, aiki mai sauƙi da ingantaccen iko.

8.Karamin tsari: ɗakin babban na'ura yana haɗa kewayen rufewa don murkushewa.

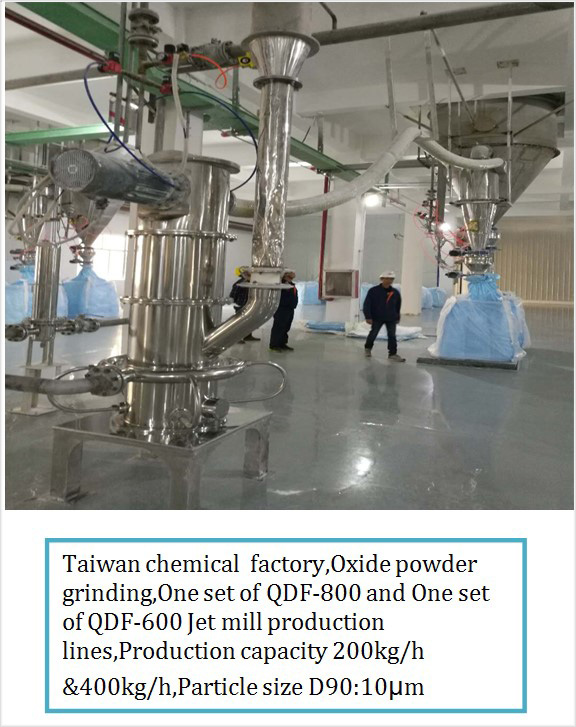

A kwarara ginshiƙi ne misali milling aiki, kuma za a iya daidaita ga abokan ciniki.

| abin koyi | QDF-120 | QDF-200 | QDF-300 | QDF-400 | QDF-600 | QDF-800 |

| Matsin aiki (Mpa) | 0.75 ~ 0.85 | 0.75 ~ 0.85 | 0.75 ~ 0.85 | 0.75 ~ 0.85 | 0.75 ~ 0.85 | 0.75 ~ 0.85 |

| Amfanin iska (m3/min) | 2 | 3 | 6 | 10 | 20 | 40 |

| Diamita na kayan abinci ( raga) | 100-325 | 100-325 | 100-325 | 100-325 | 100-325 | 100-325 |

| Lalacewar murkushewa (d97μm) | 0.5-80 | 0.5-80 | 0.5-80 | 0.5-80 | 0.5-80 | 0.5-80 |

| Iya aiki (kg/h) | 0.5-15 | 10-120 | 50-260 | 80-450 | 200-600 | 400-1500 |

| Wutar da aka shigar (kw) | 20 | 40 | 57 | 88 | 176 | 349 |

| Kayan abu | Nau'in | Diamita na abubuwan da aka ciyar | Diamita na barbashi da aka fitar | Fitowa(kg/h) | Amfanin iska (m3/min) |

| Cerium oxide | QDF300 | 400 (Rasha) | d97,4.69m | 30 | 6 |

| Mai hana wuta | QDF300 | 400 (Rasha) | d97,8.04m | 10 | 6 |

| Chromium | QDF300 | 150 (Rasha) | d97,4.50m | 25 | 6 |

| Phrophyllite | QDF300 | 150 (Rasha) | d97,7.30m | 80 | 6 |

| Kashin baya | QDF300 | 300 (Rasha) | d97,4.78m | 25 | 6 |

| Talcum | QDF400 | 325 (Rasha) | d97,10 μm | 180 | 10 |

| Talcum | QDF600 | 325 (Rasha) | d97,10 μm | 500 | 20 |

| Talcum | QDF800 | 325 (Rasha) | d97,10 μm | 1200 | 40 |

| Talcum | QDF800 | 325 (Rasha) | d97,4.8m | 260 | 40 |

| Calcium | QDF400 | 325 (Rasha) | d50,2.50m | 116 | 10 |

| Calcium | QDF600 | 325 (Rasha) | d50,2.50m | 260 | 20 |

| Magnesium | QDF400 | 325 (Rasha) | d50,2.04m | 160 | 10 |

| Alumina | QDF400 | 150 (Rasha) | d97,2.07m | 30 | 10 |

| Ƙarfin lu'u-lu'u | QDF400 | 300 (Rasha) | d97,6.10m | 145 | 10 |

| Quartz | QDF400 | 200 (Takalma) | d50,3.19m | 60 | 10 |

| Barita | QDF400 | 325 (Rasha) | d50, 1.45m | 180 | 10 |

| Wakilin kumfa | QDF400 | d50, 11.52 μm | d501.70 μm | 61 | 10 |

| Kasar gona | QDF600 | 400 (Rasha) | d50,2.02m | 135 | 20 |

| Lithium | QDF400 | 200 (Takalma) | d50, 1.30 μm | 60 | 10 |

| Kirara | QDF600 | 400 (Rasha) | d50,3.34m | 180 | 20 |

| PBDE | QDF400 | 325 (Rasha) | d97,3.50m | 150 | 10 |

| AGR | QDF400 | 500 (Rasha) | d97,3.65m | 250 | 10 |

| Graphite | QDF600 | d50,3.87m | d50,1.19m | 700 | 20 |

| Graphite | QDF600 | d50,3.87m | d50, 1.00 μm | 390 | 20 |

| Graphite | QDF600 | d50,3.87m | d50,0.79m | 290 | 20 |

| Graphite | QDF600 | d50,3.87m | d50,0.66m | 90 | 20 |

| Concave-convex | QDF800 | 300 (Rasha) | d97,10 μm | 1000 | 40 |

| Bakin siliki | QDF800 | 60 (Mashafi) | 400 (Rasha) | 1000 | 40 |